One To Two Automatic Mask Machine Disposable Medical Surgical Face Mask Machine

Product Details:

| Place of Origin: | Jiangsu, China (Mainland) |

| Brand Name: | KINGSMAN |

| Certification: | CE |

| Model Number: | Fully Automatic Mask Machine |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set/Sets |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Packing |

| Delivery Time: | 28 Days After 40% Down Payment |

| Payment Terms: | T/T |

| Supply Ability: | 30 Sets Per Month |

|

Detail Information |

|||

| Name: | Mask Making Machine | Machine Type: | Automatic |

|---|---|---|---|

| Function: | Facemask Making | Capacity: | 100-120 PCS/Minute |

| Final Products: | Mask | Place Of Origin: | China |

| Qualification Rate: | 98-99% | Mask Specification: | 175*95mm |

| High Light: | face mask machine,automatic facial mask machine |

||

Product Description

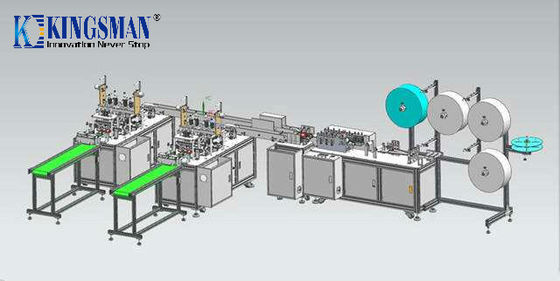

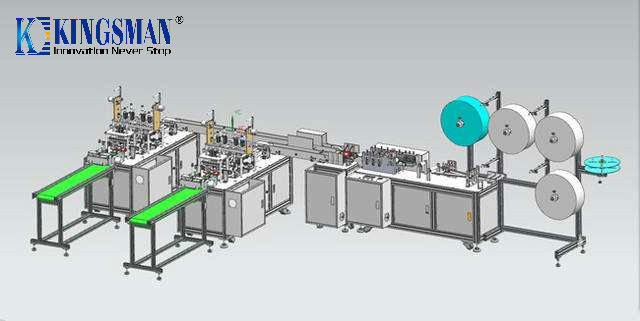

Fully Automatic One to Two Disposable Medical Surgical Face Mask Machine

Description:

This machine is mainly used for automatic forming of flat masks. After the entire roll of fabric is unrolled, it is driven by rollers, and the fabric is automatically folded and wrapped. Nose bridge rolls unrolled by traction. Cut and import into the hemmed fabric, both sides are welded to seal by ultrasonic welding, and then through the ultrasonic side seal. It is cut and shaped by a cutter ; transported to the two mask ear band welding stations through an assembly line. The final mask is formed by ultrasonic welding. After the mask is made, it is transported to flat belt line and collected.

Usage:

Making 3 layer disposable mask for common use

Making 4 layer medical mask for hosiptal use

High Production:

100-120 PCS/Minute;

Production line:

Feeding--Molding--2 Station Separator-- 2 Ear Loop Machines

Delivery:

28 days after 40% downpayment

Function introduction :

This production line is a fully automatic one-to-two mask machine, one body machine drives two ear band machines. After the main body machine

outputs the mask body, the mask body sheet is conveyed to the turning mechanism by a conveyor belt structure. The reversing mechanism is used to flip the mask plate onto the belt connected to the ear band machine, and then the mask sheet is conveyed to the first mask plate on the front of the ear band machine through the conveyor belt, and finally the mask sheet is placed on the ear band by the cylinder pressing In the mask plate of the machine, the ear band machine is used to complete the welding of the ear bands of the mask and the edging, thereby completing the production of an ear band mask product. This machine adopts PLC, touch screen control, single-phase motor for main conveyor belt, stepping motor turning, precise transmission, stable control and adjustable speed.

Product Features

1. High stability, low failure rate, beautiful appearance without rust;

2. Computer PLC programming control, servo drive, high degree of automation;

3. Photoelectric detection of raw materials to avoid mistakes and reduce waste.

The technical parameters

1. Machine size length, width, and height: the whole machine has a size of 4500mm × 5500mm × 1830mmmm;

2. Voltage: AC220V 50-60HZ

3. One-to-two production line efficiency: 100-120 tablets / min

4. Power: 8.5KW

The Main Electrical Parts Main Machine Configuration:

1.Variable frequency motor

2. Ultrasound 2 sets

3. plc control 1 set

4. 2 sets of electronic eyes Ear strap machine configuration: 1. 2 sets of variable frequency motors

![]()